-

Andres Blanco자세 제어 분사기는 정확하게 도착했습니다. 나는 ROV에 그(것)들을 시험하고 우리는 결과에 아주 행복합니다. 에폭시 실내 끝은 아주 좋 크기에 관하여 모터의 힘은 확실히 좋습니다.

Andres Blanco자세 제어 분사기는 정확하게 도착했습니다. 나는 ROV에 그(것)들을 시험하고 우리는 결과에 아주 행복합니다. 에폭시 실내 끝은 아주 좋 크기에 관하여 모터의 힘은 확실히 좋습니다. -

Gregoire LangeChangzhou 비크 기술 모터 기술과 우리의 회사 사이 협력은 다만. 우리의 필요의 좋은 이해, 우리의 문제를 해결하는 것을 중대한 의도. 나는 추천합니다!

Gregoire LangeChangzhou 비크 기술 모터 기술과 우리의 회사 사이 협력은 다만. 우리의 필요의 좋은 이해, 우리의 문제를 해결하는 것을 중대한 의도. 나는 추천합니다! -

데이비드 Molevelt직업 적이고 및 명확한 커뮤니케이션. 순서는 때 맞추어 발송되었습니다. 선적에 추가해 곳에 반대 연결관. 우리가 동의했는 처럼 운전사 일!

데이비드 Molevelt직업 적이고 및 명확한 커뮤니케이션. 순서는 때 맞추어 발송되었습니다. 선적에 추가해 곳에 반대 연결관. 우리가 동의했는 처럼 운전사 일! -

Buildstorm 개인적인 한정된제품은, 그것 좋게 포장되었습니다 예상대로 작동합니다. 판매인은 아주 빨리 반응하고 사는 결정을 내리기에서 돕습니다. 그들은 당신을 위한 제품을 주문을 받아서 만들게 준비되어 있습니다.

Buildstorm 개인적인 한정된제품은, 그것 좋게 포장되었습니다 예상대로 작동합니다. 판매인은 아주 빨리 반응하고 사는 결정을 내리기에서 돕습니다. 그들은 당신을 위한 제품을 주문을 받아서 만들게 준비되어 있습니다. -

Ashley Griffin선적은 아주 빨리 받아졌습니다. 제품은 포장해서 잘 보호되었습니다. 회사 rep는 따뜻해고 친절했습니다. 등급 플러스 A!

Ashley Griffin선적은 아주 빨리 받아졌습니다. 제품은 포장해서 잘 보호되었습니다. 회사 rep는 따뜻해고 친절했습니다. 등급 플러스 A!

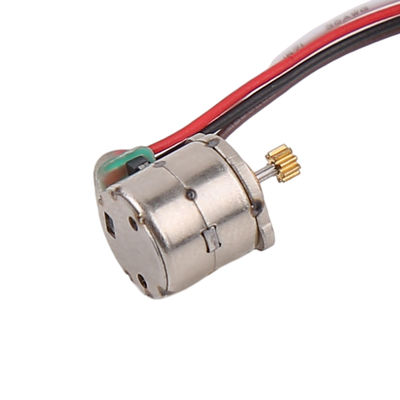

Vic-Tech 2 Phase 4 Wire Stepper Motor , 3.3V DV Stepping Motor 8mm

무료샘플과 쿠폰을 위해 나와 연락하세요.

왓츠앱:0086 18588475571

위챗: 0086 18588475571

SKYPE: sales10@aixton.com

만약 당신이 어떠한 관심도 가지면, 우리가 24 시간 온라인 도움말을 제공합니다.

x| 유형 | 3.3 V 스텝 모터 | 단계 각(급) | 18' |

|---|---|---|---|

| 전압 | 3.3V DC | 단계 | 2개 단계 |

| 저항 | 40 오옴 | 모터 직경 | 8mm |

| 토크 | 0.9-1.2g.cm | 단계 수 | 2개 단계 |

| 강조하다 | 3.3V stepper motor 8mm,2 phase 4 wire stepper motor,micro stepper motor with warranty |

||

8mm micro stepper motor Long life 2 phase 4 wire 3.3V DC mini stepping motor

![]()

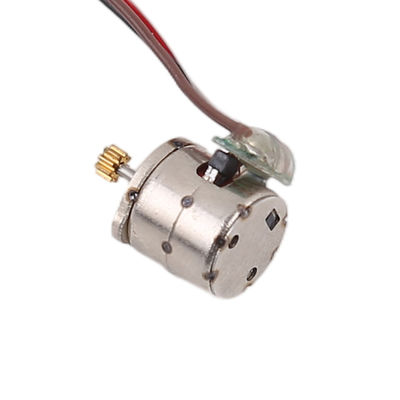

VSM08133 is a precision micro stepping motor body outer diameter 8MM, body length 8.2MM, shaft outer diameter 1MM, the shaft length can be changed according to the needs, and can be equipped with gears, pulleys,

Corresponding output devices such as worm and screw.

The motor has a basic step angle of 18 degrees and the motor runs 20 steps per week.

Because of its small size, high precision, and easy control, this miniature stepper motor is widely used in cameras, optical instruments, lenses, flashlights, precision medical equipment, automatic door locks and other fields.

The motor input part of the FPC, but can according to the customer demand can be changed to a connecting line needle, PCB and other forms.

The mounting bracket can be changed according to the customer's request.

At the same time, we can match the corresponding drive system to meet the needs of customers!

Our team has more than 10 years of stepper motor design, development and production experience, so we can achieve product development and auxiliary design according to the special needs of customers!

Customer needs are our efforts, please feel free to contact us!

This miniature motor is mainly used in cameras, lenses, optical instruments and other fields. The light needle is relatively small in size and the control is very precise. The needs of customers are the direction of our efforts, and meeting the needs of customers will be our highest pursuit. If you have needs, please feel free to keep in touch with us.

8mm micro stepper motor parameter sheet:

| PRODUCT NAME | 8 MM MICRO STEPPER MOTOR |

| MODEL | VSM08133 |

| RATED VOLTAGE | 3.3 V DC |

| COIL RESISTANCE | 40Ω±10% |

| NO.OF PHASES | 2 PHASES |

| STEP ANGLE | 18°/STEP |

| MAX. STARTING FREQUENCY | 1000 PPS min. (AT 3.3 V DC) |

| MAX. SLEWING FREQUENCY | 1200 PPS min. (AT 3.3 V DC) |

| PULL IN TORQUE | 0.8 gf-cm min. (AT 480 PPS , 3.3V DC) |

| PULL OUT TORQUE | 1.0 gf-cm min. (AT 480 PPS , 3.3V DC) |

| INSULATION CLASS | CLASS E FOR COILS |

| INSULATION STRENGTH | 100V AC FOR ONE SECOND(3mA MAX) |

| INSULATION RESISTENCE | 1 MΩ (DC 100 V) |

| OPERATING TEMPERATURE RANGE | -10~+60 ℃ |

| OEM & ODM SERVICE | AVAILABLE |

8mm micro stepper motor outside drawing:

![]()

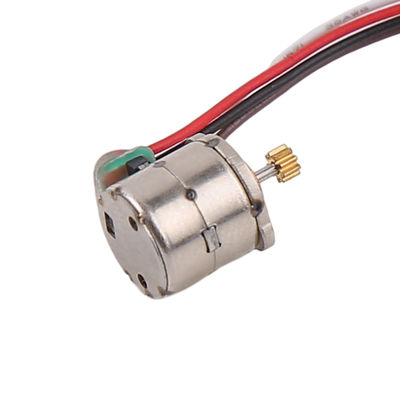

Product display:

8mm Stepper Motor 3.3V DC 2 Phase 18 Degree Step Angle Micro Stepper Motor

![]()

The principle of stepper motor is as follows:

1. The stepper motor is controlled by pulse signal. Each time a pulse is input, the stepper motor is pushed forward one step.

2. The rotation step angle of the stepping motor is based on the structure of the motor and is realized in a certain proportion.

3. In practice, there will be slight differences in the rotation step angle of the motor. This is because the structure of the motor is fixed, and the total number of poles will not be accumulated, and the higher the processing accuracy will be. In general, the step angle of an industrial hybrid stepper motor is 1.8°, or 200 poles.